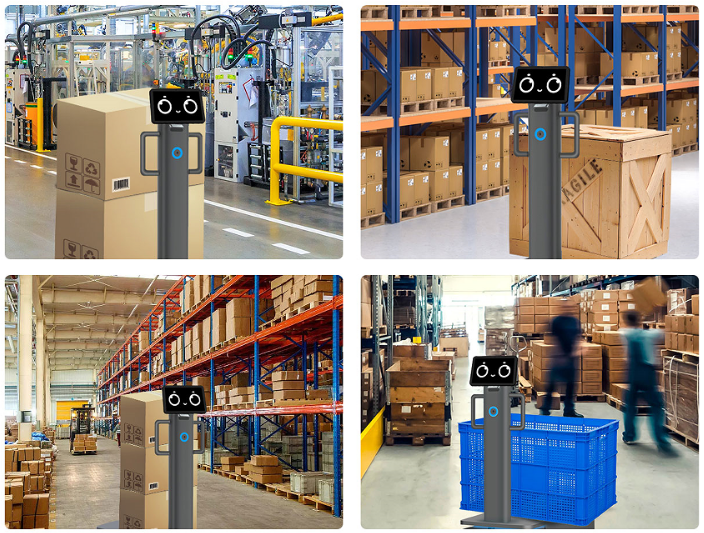

With the rapid development of modern manufacturing industry today, the efficiency and safety of material distribution inside the factory have become the key factors for enterprises to enhance their competitiveness. Suzhou Alpha Robotics Co.,Ltd with excellent research and development strength, launched the Oxbot factory delivery robot, with its advanced technology, strong performance and excellent safety, for the factory logistics has brought revolutionary solutions.

A powerful, intelligent brain

Oxbot has built-in SmartStar vertical large model developed by Suzhou Alpha Robotics Co.,Ltd, and this powerful “intelligent brain” gives the robot extraordinary ability. It can autonomously complete the gate traffic, easily through the various access control areas of the factory; Can take the ladder independently, to achieve efficient distribution between different floors; Support remote call function, so that managers can flexibly schedule according to actual needs; It also has the ability to automatically recharge, without human intervention, to ensure that the robot always maintains sufficient “physical strength” to work. With the blessing of SmartStar’s large model, Oxbot is like a trained logistics expert, accurately and efficiently completing every delivery task.

Three models to meet a variety of load requirements

Oxbot has three models, Oxbot F150, Oxbot F300 and Oxbot F500, which can meet the diverse load requirements of different plants. Among them, the Oxbot F500 has a large load capacity of 500KG, which is called the “hercules” of factory logistics. Its fuselage is supported by 80% high-hardness aluminum alloy, which is not only stable, but also able to withstand huge weight. For repetitive and cyclical goods transportation, Oxbot’s powerful load capacity can greatly improve the efficiency and reliability of goods operation, providing solid logistics support for the production process of the factory.

Super heavy load capacity

Oxbot has a large load capacity of 500KG, and the fuselage is supported by 80% high-hardness aluminum alloy, which is extremely stable. This strong load capacity makes it easy to cope with repetitive and cyclical goods transport tasks, whether it is heavy machinery parts or large quantities of raw materials, can be safely and stably transported, widely used in various factory scenarios, effectively improving the efficiency and reliability of goods.

Advanced obstacle avoidance and navigation system

1.40m laser radar autonomous obstacle avoidance: Equipped with 40m laser SLAM navigation system, Oxbot is like a keen “eye”, which can shuttle freely in tens of thousands of square meters of factory buildings and accurately avoid various obstacles. Whether it is a narrow channel or a complex production equipment layout, it can flexibly respond to ensure the smooth progress of distribution tasks and meet the needs of use in a variety of scenarios.

2.RGBD binocular HD camera: In addition to Lidar, the robot is also equipped with RGBD binocular HD camera, and the upper and lower two binocular cameras work together with Lidar to achieve three-dimensional intelligent obstacle avoidance. This enables it to sense the surrounding dynamic environment in real time, identify and avoid obstacles more accurately, and further improve the safety of operation.

Large screen and safe and reliable battery guarantee

The large 13.3-inch screen is one of the highlights of Oxbot. It can not only clearly display information query, map display and other content, so that operators can easily understand the robot’s operating status and task details, but also make human-computer interaction more convenient and efficient. Whether it is to set the delivery route or to view the status of the device, it is clear at a glance, which greatly improves the user experience.

Oxbot uses a safer lithium iron phosphate battery with a 24V40AH battery capacity. This battery has the advantages of high temperature resistance, non-explosion and non-combustion, providing a reliable energy guarantee for the operation of the robot, so that users do not need to worry about safety issues. At the same time, its long service life also reduces operating costs, providing strong support for the long-term stable use of robots for enterprises.

Excellent pass performance

There are often obstacles such as thresholds and grooves between the production lines of factories, which puts high requirements on the passability of robots. Oxbot is equipped with 8-inch main drive wheels and 5-inch extra-large double-row cardan wheels, which have a lot of power. It can easily overcome 30mm thresholds and 40mm grooves, facilitating precise material transfer between production lines. At the same time, this excellent passability also meets the requirements of autonomous escalator, so that the robot can freely switch between different floors to achieve a full range of material distribution.

The fastest speed of Oxbot factory delivery

robot can reach 2m/s, the minimum passability is 80cm, and the navigation mode of Lidar SLAM is adopted, and all performance indicators are excellent. It is like an all-round logistics assistant, which can help factories improve logistics efficiency, reduce labor costs, and improve production safety. Choosing Oxbot is to choose the intelligent upgrade of factory logistics and open a new era of efficient, safe and convenient logistics!

Post time: Feb-11-2025